3. NEEDLES

Needles for industrial sewing machines Needles for industrial sewing machines | |  Needles for household sewing machines Needles for household sewing machines | |

Lapp is an authorizes Groz-Beckert distribution partner for

Sewing and shoe machine needles

Groz-Beckert needles for all kind of sewing machines...

SEWING MACHINE NEEDLES YOU CAN TRUST...

Groz-Beckert is the worlds leading provider of industrial needles,

precision components and fine tools as well as systems and services

for the production and joining of textile surfaces.

The products and services support the fields of

Knitting, Weaving, Felting, Tufting and Sewing.

Founded in 1852, the company today has approximately 8,000 employees

and generates sales of nearly 570 million Euros.

Groz-Beckert is active worldwide, with agencies, production plants

and distribution subsidiaries in over 150 countries.

Sewing-machine and shoe-machine components from Groz-Beckert

offer precision and lasting connections in the smallest of spaces. Whether textiles, leather or other materials:

make use of the full potential of Groz-Beckert products for

joining textile surfaces.

Experience how miniaturized - seemingly simple – tools

can have a considerable effect on productivity and seam quality,

as well as being gentle on material.

Continuously increasing machine speeds and a growing variety of

material and thread qualities mean you should rely on

proven technologies for sustainable success!

SEWING MACHINE

NEEDLES

FROM

SEWING MACHINE NEEDLES YOU CAN TRUST...

You can buy needles direct from us

Just inform needles system, size and quantity

Here is some examples of needles prices

e.i. for each 100 pcs. excl. shipping

134 134FG 1128 1738 1738FG DBxK5

DBxK5FFG

$ 30.-

134GEBEDUR 135x17 332 1738GEBEDUR

$ 41.-

134-35 134MRFFG 2091

$ 47.-

134LR 134-35LR B27 B63

$ 50.-

29-49

$ 171.-

Look above for certain needles system for

Industrial and household needles

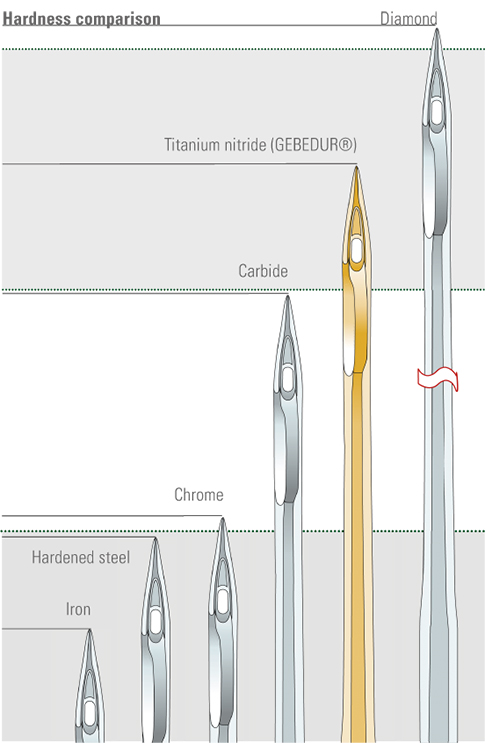

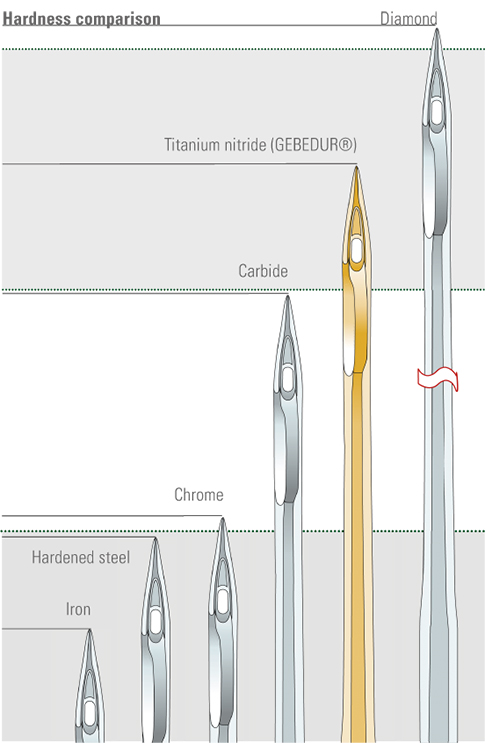

GEBEDUR® coating Besides the chromium coating – which is standard for most sewing machine needles – Groz-Beckert also offers needles with GEBEDUR® coating. These needles are titanium nitride coated and can be distinguished from standard needles by their "golden" appearance. | With their titanium nitride coating the GEBEDUR® needles have a higher hardness than standard needles. Additionally, they are better protected against wear and damage. Therefore, GEBEDUR® needles are primarily used in applications where the point and the eye area tend to fast wear. For this reason, all SAN® 5 and SAN® 6 needles are GEBEDUR® coated to meet the extreme requirements. The GEBEDUR® coating does not lead to a higher stability of the needle, since its geometry corresponds to that of the standard needle. The higher wear resistance of GEBEDUR® needles in the point and eye area, however, leads to a uniform and high seam quality and a longer lifetime of the needle, resulting in increased productivity.

|

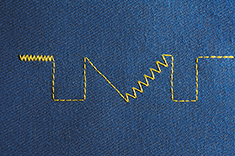

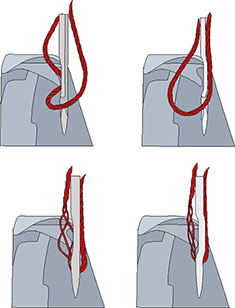

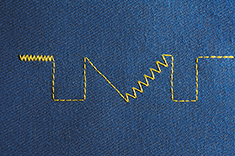

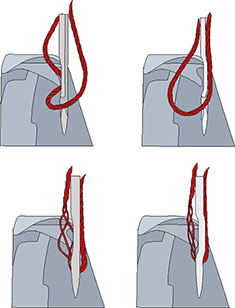

MR needle – developed for automated sewing processes with multidirectional feeding systemsIn the entire sewing industry, an increasing number of computerized sewing machines are in operation, putting high demands on the sewing machine needles. Especially when changing the sewing direction, when the thread is pulled out of the needle eye in different directions, there can be changes in the thread twist. This can lead to instable loop formation. Standard sewing needles are frequently unable to meet these requirements, resulting in problems such as needle breakage, untidy seams (skipped stitches, thread breakage), and material damage. The Groz-Beckert MR needle was developed in order to reduce these problems and improve the seam quality as well as the machine efficiency.

| Special features of MR needles- Special blade and scarf geometry → outstanding bending resistance (deflection resistance) → extreme stability

- Very deep and extended scarf → extremely tight adjustment of the looper/hook to the needle possible optimum protection of the thread

- Special asymmetrically shaped thread gliding area inside the eye → stable loop formation (also when changing the sewing direction) + prevention of negative loop formation and thread twist

- Special thread guiding → reduction of unwinding of the thread

| |  Comparison loop formation between standard needle (left) with MR needle (right) with low thread tension Comparison thread pickup between standard needle (left) with MR needle (right) with high twist shifting

| Benefits of MR needles at a glance- Less needle breakage

- Extremely tight adjustment of looper/hook to needle possible

- Optimum security against skipped stitches

- Less thread splicing

- Less thread breakage

- Optimum protection of the fabric

- High productivity due to reduced machine downtime

- Reduced production costs

|

|

Ask for other systems by sending us an e-mail with your inquiry

info@lapp-denmark.dk

To distinguish the different sewing machine needles, each needle has its specific designation. This designation consists of 3 or 4 components: needle system, point style, needle size and, were required, coating: Bsp: 134 FFG GEBEDUR Nm 100

(system) (point style) (coating) (needle size) For a clear identification of a sewing machine needle, these 4 components must be known. | Needle systemThe needle system stands for the basic features of the needle (shank diameter, length from butt to eye, number of grooves, point length) that determine in which machines the relevant needle fits. The needle system can either consist of numbers (e.g. 134, 134-35) or of a combination of numbers and letters (e.g. UY 128 GAS, DBX1). As the designation for one and the same needle can vary from producer to producer, the labels of Groz-Beckert also list foreign designations. Thus, the needles can be clearly identified and confusion is avoided.

| | Sewing needles are available in various point styles. This variety is needed to meet the requirements of different materials. Basically, point styles are divided into cloth points (round points) and cutting points. | | The standard point of a needle system is normally not indicated in the designation. This applies, for example, to the "R" point for all lockstitch needles and the "RG" point for all chain stitch needles. Also for the point style, each sewing needle producer has an own designation. The "myGrozBeckert" app – available free of charge from the App Store – features a tool to identify the corresponding designations. | Needle sizeThe needle size is the diameter of the needle, measured directly above the scarf. Groz-Beckert indicates the needle size according to the numeric metric system (= Nm). The Nm value is the diameter multiplied by 100.  Besides the numeric system, there is also a system that indicates the needle size in numbers. It is mainly used in Asia. The "myGrozBeckert" app also offers a tool for the conversion of the two systems.

| CoatingStandard sewing machine needles are generally chrome-plated. Besides this, there are also GEBEDUR® needles with titanium nitride coating with a significantly higher resistance to wear and point damage. The standard coating is not mentioned in the needle designation. Only GEBEDUR® needles bear the relevant remark in their designation, as in the above example. |  Chromium coated needles  GEBEDUR® coated needles

|

|

Needles for industrial sewing machines

Needles for industrial sewing machines